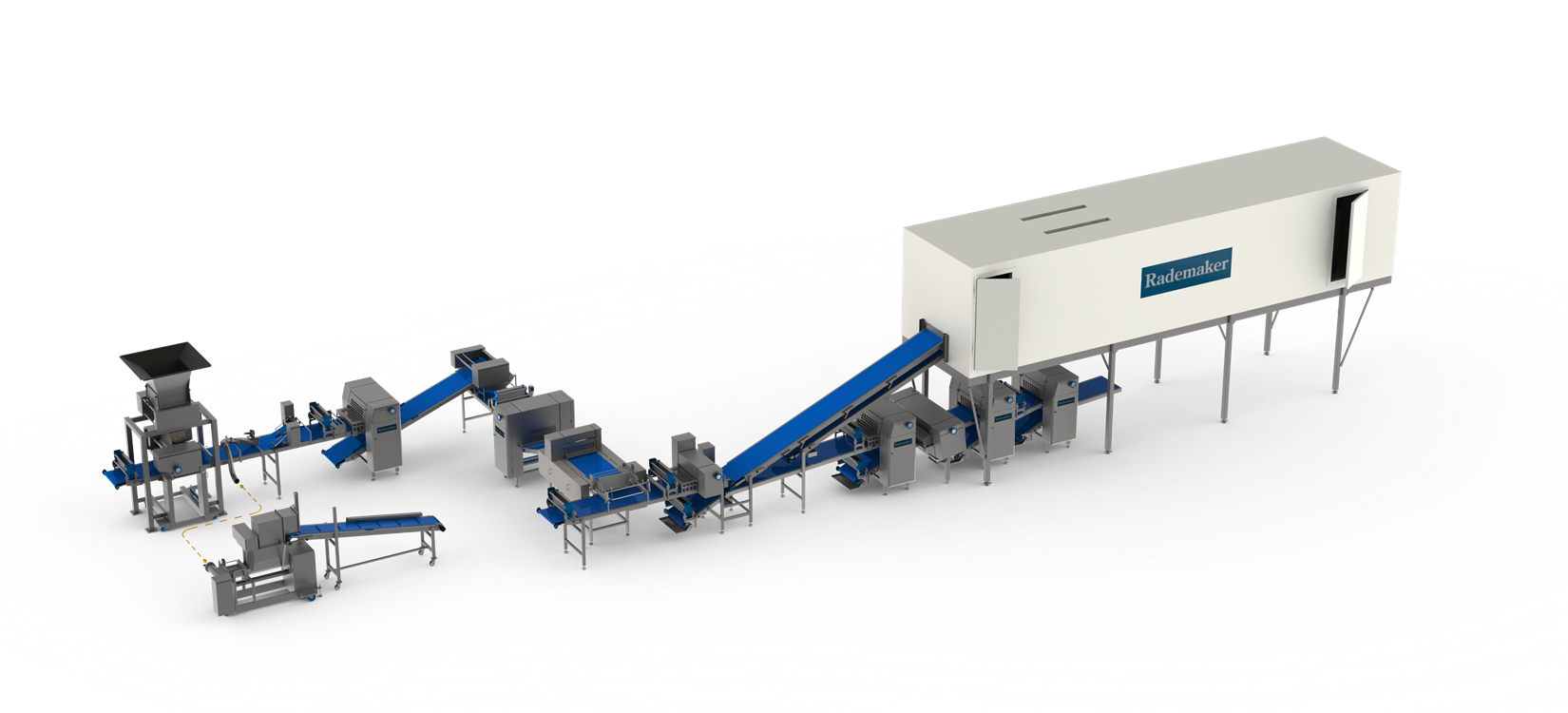

SIGMA 叠层起酥生产线

Pre-sheeter

Rademaker dough pre sheeters generate consistent, high end stress-free dough sheets. Our pre-sheeters are able to process a wide range of doughs.

Fat-pump

Especially for the laminating process, Rademaker developed a fat-pump capable of processing virtually all types of fat under the right circumstances. The pump produces a continuous fat sheet. The pump is mobile and can be fully dismantled for fast and easy cleaning. The accuracy of the Rademaker fat-pump makes the pump well respected.

Reduction station

Reducing steps for a consistent, quality dough sheet (width and thickness).

Laminating

Laminating the dough-sheet (up to 512 layers) depending on the line concept. Several laminating methods are possible, depending on the layout of the Sigma© Laminator and the amount of layers that is desired.

Cooling and Resting

Cooling & Resting are proven steps in the continuous processing of laminated & sheeted dough. Integrating these processes in a (semi-) automatic production line requires specific skill and high-level engineering in order to meet high product quality standards. The cooling process ensures that the integrity of the layers remains intact resulting in a perfect consistency of fat & dough. Subsequently the resting process enables your products to obtain the best possible taste and shape / volume, that is resulting from a combination of dough relaxation (stress reduction) and controlled yeast activity.

The Rademaker Cooling and Resting concept is a unique system in the market, based on the indirect air coolant principle. This principle fully excludes chemical cooling agents in the process and is developed with the highest hygiene requirements. The continuous external air treatment prevents condensation in cooling area. The system can fit in every required layout due to the modular build. Our system guarantees safe positioning, handling & tracking of the dough.

Laminating

Laminating the dough-sheet (up to 512 layers) depending on the line concept. Several laminating methods are possible, depending on the layout of the Sigma© Laminator and the amount of layers that is desired.

通过高级流程控制和宽度增加实现有效生产

轻松维护、最低故障停机时间促使降低成本

快速轻松清洁

人性化操作

显著降低的能源用量

能力

我们的 Sigma© 叠层起酥生产线旨在为中等规模到工业化规模的烘焙公司生产一系列产品种类。产能范围从 250 kg/hr 到 10,000 kg/hr 不等,可全天候持续生产。

用于生产羊角面包和甜点的叠层面片

工作宽度

› 600 mm

› 800 mm

› 1,000 mm

› 1,200 mm

› 1,400 mm

› 1,600 mm